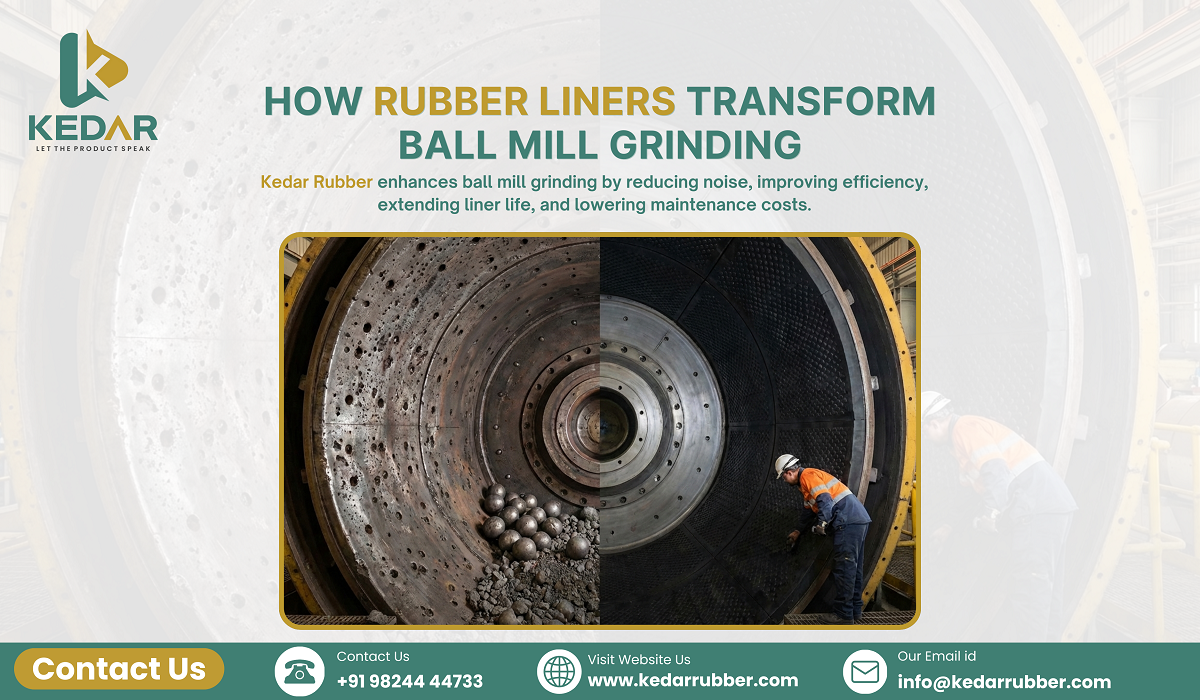

Transforming Ball Mill Grinding Processes with Kedar Rubber Products

Industries such as mining, cement, metal processing, ceramic manufacturing, and bulk material handling operate in some of the harshest mechanical environments in industrial plants. Continuous abrasion, repeated impact loads, corrosive slurries, vibration, and extended operating cycles place enormous stress on equipment. For plant engineers and maintenance teams, the key challenge is not only maintaining consistent output but also ensuring reliability, minimizing downtime, and reducing lifecycle costs. This is where how rubber liners transform ball mill grinding becomes critical, providing enhanced wear resistance, improved energy efficiency, and longer equipment life.

Across global industrial sectors, including India’s booming mining zones and production hubs, there’s a noticeable shift towards engineered wear protection rather than routinely swapping out parts. Keeping machinery dependable, adhering to safety norms, and having foreseen upkeep schedules are now as crucial as maximizing output.

In this setting, Rubber Liners for Ball Mills hold significant importance. They aren’t simply disposable items in the usual sense, but expertly designed pieces meant to protect vital milling machinery, absorb energy from impacts, and keep processes steady over extended production runs.

Industrial Hurdles Fueling the Need for Ball Mill Rubber Liners

In severe industrial settings, failures caused by wear rarely stem from a single factor. They typically arise from multiple stresses interacting with one another.

- Friction: Ground-up ore chunks, clinker, minerals, and grinding media constantly rub against the mill’s inner surfaces. Steel linings degrade steadily, leading to uneven contours and less effective grinding.

- Impact Forces: During milling, falling media and incoming material generate recurring, high-force impacts. Over time, this hastens material fatigue in hardliner systems.

- Deterioration: In wet grinding setups, chemical exposure and moisture contribute to corrosive action, especially in mining and metal processing tasks.

- Production Halt Pressure: Unscheduled stoppages for liner changes disrupt output plans and raise operational risks.

- Upkeep Expenditures: Frequent liner substitutions involve labor, lifting apparatus, and safety considerations, adding hidden overhead beyond the liner’s price tag.

These issues are widespread across Indian mining areas, from iron ore regions to cement complexes and ceramic centers, and are comparable to those in comparable worldwide industrial settings.

What Constitutes a Ball Mill Rubber Liner?

A Ball Mill Rubber Liner acts as a protective barrier, fitted inside grinding mills to shield the shell and improve the machine’s performance. Unlike hard metallic linings, rubber ones are crafted to absorb impact energy while resisting surface wear.

They usually comprise specially formulated elastic materials, sometimes enhanced with ceramic or metal reinforcements in areas experiencing heavy wear. Their purpose isn’t aggressive grinding enhancement, but safeguarding the equipment while maintaining consistent milling conditions.

There’s no single standard for the “finest” liner. A rubber liner’s suitability hinges on the mill’s size and speed, the material being processed, the operating atmosphere, and the maintenance approach.

Uses Across Different Sectors

- Mining Sector: In mining activities, rubber linings are widely used in secondary and tertiary mills where impact loads are moderate but abrasive action is constant. Seasoned plant operators often note more consistent liner longevity and reduced noise compared to conventional steel setups.

- Cement Facilities: Cement grinding processes benefit from rubber linings due to their ability to dampen vibrations and their predictable wear patterns, which help maintain mill equilibrium over extended operating periods.

- Metal & Steel Facilities: During material prep and refinement phases, rubber linings help manage abrasive fine particles and wet slurry conditions without significant corrosion hazards.

- Ceramic Production: Plants processing alumina, silica, and specialized minerals utilize rubber and ceramic wear defenses to control impurity introduction and maintain precise internal dimensions within mills.

- Power Generation Facilities: Coal grinding and ash management systems rely on wear protection methods to reduce failures caused by erosion and unexpected downtime.

- Bulk Material Handling: Beyond the mills themselves, rubber lining systems extend to chutes, bins, and conveyor transfer points, forming a holistic wear control strategy.

Material Science & Engineering Aspects

Wear defense is fundamentally a challenge in materials engineering.

- Rubber Characteristics: Industrial rubber mixes are formulated for flexibility, resistance to tearing, and appropriate firmness. The aim isn’t peak hardness, but optimal energy absorption without premature splitting.

- Ceramic Firmness: In areas of intense abrasion, ceramic wear tiles provide extreme hardness. When incorporated correctly, they supplement rubber by handling acceptable abrasive wear.

- Wear Resistance Concepts: Abrasion resistance relies on the compound’s makeup, how particles interact, and the surface’s ability to recover. Impact resistance depends on elasticity and controlling the rebound.

- Impact Dampening: Rubber linings reduce the peak stress transferred to the mill shell, thereby extending the equipment’s structural life.

Producers with extensive industry background recognize that material choice is application-dependent, not dictated by a simple product list.

Design & Tailoring Needs

No two milling operations run under identical conditions.

- Equipment Fit: Liner design must align with mill dimensions, lifter arrangement, bolt patterns, and mill rotation.

- Precise Sizing: Even minor differences in size can cause installation trouble or inconsistent wear.

- Task-Specific Design: The size of the input material, mill RPM, and operating temperature influence the liner’s thickness, the chosen compound, and the reinforcement method.

This level of customization requires engineering expertise, not just picking generic items.

Manufacturing Quality & Process Oversight

Uniformity in industrial wear components is vital.

Accurate manufacturing guarantees dimensional correctness across production batches. Quality checks include compound testing, hardness verification, bond strength testing, and visual assessment. Consistent batches decrease variation in wear behavior, helping maintenance teams schedule stoppages more reliably.

Process control is significant for rubber-ceramic combinations, where bonding quality directly affects operational duration.

Fitting & Servicing Points

Rubber linings are generally less heavy than their metal counterparts, which can simplify handling and mounting.

Lower installation weight often results in:

- Quicker turnaround times for stoppages

- Reduced the need for heavy lifting gear

- Enhanced safety during liner replacement

Maintenance schedules become more predictable when wear patterns are even. Seasoned maintenance crews prefer linings that degrade progressively rather than failing abruptly.

Safety & Operational Dependability

Safety is closely linked to managing wear.

Well-conceived rubber linings mitigate noise and vibration and reduce the risk of liner fragments breaking. This improves working conditions both while running and during maintenance. Protecting the equipment also means fewer urgent fixes, contributing to overall plant trustworthiness.

Cost Effectiveness Over the Equipment’s Lifespan

Cost efficiency isn’t just about the liner’s initial price.

Savings across the equipment’s service life come from:

- Fewer unexpected production halts

- Less maintenance staff time needed

- Prolonged life for the mill shell

- Better organization of upkeep activities

In mining and metal processing operations, these secondary benefits often outweigh the initial material expense.

Export Readiness & Worldwide Acceptance

Buyers in global industrial arenas expect more than just product delivery.

Export preparedness encompasses:

- Technical documentation

- Tracking the origin of materials

- Awareness of quality standards

- Packaging appropriate for long transit

Global acceptance is built upon consistent performance, not just assertions.

Why are Experienced Producers Important?

Wear protection systems are not basic commodities.

Manufacturers with engineering expertise and deep industry knowledge grasp operational realities such as shutdown pressures, equipment limitations, and maintenance challenges. Dependable supply, technical assistance, and design insight are as valuable as manufacturing skill.

About Kedar Rubber Products

Kedar Rubber Products Pvt. Ltd. is a seasoned industrial manufacturer specializing in Rubber Liners for Ball Mills, ceramic wear defenses, rubber lining systems, rubber goods for ball mills, and conveyor solutions.

Serving industrial customers across all parts of India—including Gujarat (Ahmedabad, Surat, Vadodara), Maharashtra (Mumbai, Pune, Nagpur), Rajasthan (Udaipur, Jaipur), Odisha, Chhattisgarh, Jharkhand, Karnataka, Tamil Nadu, Andhra Pradesh, Telangana, West Bengal, Madhya Pradesh, Uttar Pradesh, Bihar, Punjab, Haryana, Himachal Pradesh, Uttarakhand, Assam, and other territories—Kedar Rubber Products supports mining zones, cement complexes, metal plants, ceramic hubs, and bulk material facilities.

Further information is available at 👉 https://www.kedarrubber.com/

In Summary:

Rubber Liners for Ball Mills are a crucial element in contemporary industrial defense strategies against wear. When expertly designed and implemented, they boost equipment reliability, foster safer working conditions, and help facilities manage long-term maintenance challenges.

For industries subjected to ongoing mechanical strain, careful liner selection and support from an experienced manufacturer directly lead to operational steadiness.

Key Takeaways

- Effective wear defense improves equipment dependability

- Rubber liners manage impact and friction in demanding settings

- Suitable for use across mining, cement, metal, ceramic, and power sectors

- Foreseeable wear supports organized upkeep

- Proven significance in both Indian and global industrial arenas

Frequently Asked Questions

1. What is the typical duration a rubber liner for a ball mill lasts?

- Duration varies based on the ore type, mill speed, and operating environment. Seasoned plant operators often gauge success by how evenly the liner wears rather than adhering to fixed timeframes.

2. Are rubber linings appropriate for heavy-duty mining tasks?

- Yes, particularly in secondary and tertiary milling, where a balance between impact and abrasion needs to be struck.

3. How frequently do rubber linings need servicing?

- Inspection cycles depend on operating hours and material properties, but service intervals are generally predictable.

4. Rubber versus ceramic wear solutions – which is superior?

- They fulfill different roles. Rubber absorbs shocks, while ceramic resists wear.

#BallMillRubberLiner #CeramicWearProtection #RubberLining #MiningSolutions #ConveyorSolutions #kedarrubberproduct #WearProtection #IndustrialManufacturing