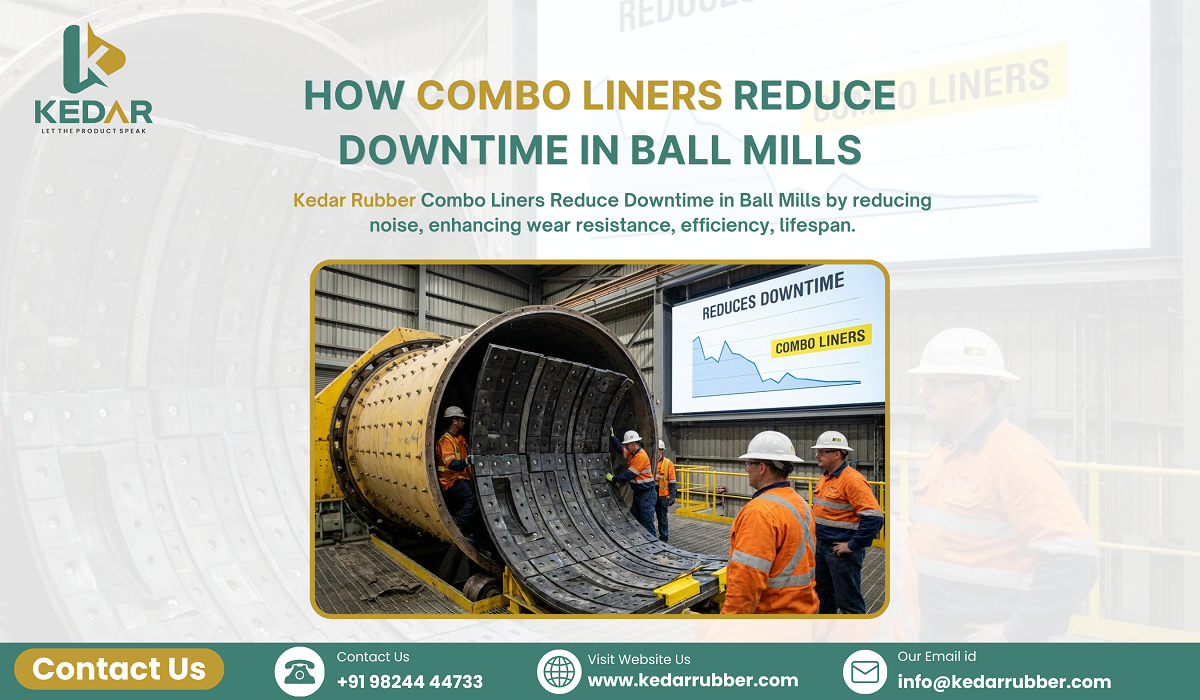

Reducing Ball Mill Downtime with Advanced Combo Liners by Kedar Rubber Products Pvt. Ltd.

In heavy-duty industrial environments such as mining, metal processing, cement manufacturing, ceramics production, and bulk material handling, equipment reliability is a non-negotiable priority. Abrasive ores, high-impact loads, corrosive slurries, and extreme operating temperatures place constant stress on essential plant components, including ball mills, chutes, conveyor belts, and hoppers. Understanding how combo liners reduce downtime in ball mills is crucial, as even minor wear or unexpected equipment failure can quickly lead to costly downtime, operational bottlenecks, and increased maintenance demands.

Producers with extensive backgrounds in the sector recognise that appropriate wear defence mechanisms are not extras but are crucial for maintaining steady output, minimising unexpected service, and extending the service life of industrial equipment.

Among the various protective assemblies, Combo Liners stand out as a vital industrial answer. By combining technologies for rubber, ceramic, and composite wear defence, these liners address roughness, shock, and erosion simultaneously. Their increasing acceptance mirrors the growing industrial need for resilient, adaptable, and effective wear protection systems, notably in mining centres across Odisha, Jharkhand, Chhattisgarh, Karnataka, and Rajasthan; metal and steel hubs in Gujarat and Maharashtra; and ceramic complexes in West Bengal, Tamil Nadu, and Andhra Pradesh.

Industrial Hurdles Fueling Demand for Combo Liners

In mining and metal-handling tasks, plant supervisors frequently find that equipment degradation stems not only from mechanical wear but also from operational and environmental factors. Several difficulties necessitate the use of advanced liners:

- Abrasion: Corrosive materials, such as iron ore, coal, limestone, and powdered ceramics, cause surface deterioration in chutes, ball mills, and storage bins. Conventional steel surfaces experience rapid material loss, reducing effectiveness and requiring frequent swaps.

- Impact Forces: Heavy chunks of ore or bulk items falling into grinding mills or onto conveyor chutes generate considerable shock pressures. Lacking sufficient shock absorption, the gear undergoes structural strain and early breakdown.

- Corrosion: Dampness, chemical additives, and metal slurries accelerate rusting. Even minor corrosion can weaken structural components, leading to costly repairs and production halts.

- Stoppage Time: Unplanned halts due to wear-related failures directly hit plant productivity. Veteran plant staff often point out that the cost of downtime far exceeds the cost of proactive wear solutions.

- Servicing Expense: Frequent liner changes and high-maintenance schedules increase running costs. Durable, tough-wear solutions reduce these recurring outlays.

Across the worldwide industrial landscape, these concerns are widespread—from iron ore ventures in Australia to ceramic factories in Italy and cement facilities in the Middle East. This positions Combo Liners as an appealing solution for plants seeking continuous operation, apparatus safeguarding, and output enhancement.

What Defines Combo Liners?

Combo Liners are heavy-duty protective setups engineered for demanding machinery in environments prone to scraping and heavy impact. They typically unite rubber and ceramic elements, capitalising on the distinct strengths of each substance:

- Rubber Linings: Offer shock absorption, flexibility, and noise reduction. Rubber’s pliable nature allows it to buffer heavy loads, preventing structural stress.

- Ceramic Pieces or Inserts: Provide superior abrasion resistance, ensuring high-wear zones retain their integrity for longer.

By integrating these parts into a single solution, Combo Liners shield equipment surfaces, enhance facility safety, and prolong component life without compromising operational effectiveness.

Uses Across Various Sectors

- Mining Operations: In extraction, Combo Liners guard ball mills, trommels, chutes, and feeding devices. Their layered structure reduces abrasion from ore, while the rubber section absorbs impact, easing strain on steel frameworks.

- Cement Factories: Cement grinding involves high-speed material movement that wears down mill linings, bins, and conveyor systems. Combo liners provide wear resistance and vibration damping, supporting steady flow and reducing unexpected servicing.

- Metal & Steel Plants: In the production of steel and other metals, slag, ores, and hot metal chips can rapidly degrade surfaces. Experienced plant operators frequently observe that rubber-ceramic composite liners extend the utility of chutes, hoppers, and mill interiors, improving operational dependability.

- Ceramic Production: High-density ceramic powders and tiles cause abrasive wear in presses, storage units, and conveyors. Ceramic additions in combo liners provide excellent wear resistance, while the rubber backing cushions machinery from recurring jolts.

- Power Stations & Bulk Material Handling: Facilities that use coal or biomass handle abrasive fuels that can damage conveyor belts and chutes. Combo liners decrease wear, maintain material passage, and prevent costly production interruptions.

Material Science & Engineering Factors

The selection of materials for Combo Liners is rooted in engineering concepts:

- Rubber Attributes: Premium industrial rubber grants elasticity, shock dampening, and vibration control. Rubber resilience, tensile power, and resistance to oil, moisture, and temperature shifts are vital for longevity.

- Ceramic Toughness: Modern ceramics, such as alumina or silicon carbide, are exceptionally hard (usually 1,500–2,000 HV) and excel at fighting abrasion. Ceramic tiles can withstand concentrated wear while minimising material loss.

- Wear Resistance Principles: Merging soft and hard layers balances energy retention and abrasion defence. Supple rubber diffuses impact, while hard ceramic resists cutting and grinding wear.

- Impact Damping: Rubber-backed ceramics prevent cracks from spreading in tiles under high-impact applications, a key consideration for ball mill and conveyor applications.

This coupling ensures combo liners function dependably in intense industrial settings.

Design & Tailoring Needs

Combo liners are not universal in scope. Successful design takes into account:

- Apparatus Fit: Liners must match the contours of ball mills, hoppers, chutes, or conveyors. A bad fit can create voids, leading to faster wear or material buildup.

- Custom Dimensions: Tile measurements, rubber thickness, and bolt configurations are determined by specific operational loads and equipment sizes.

- Application-Specific Layout: The mining, cement, steel, and ceramic sectors each require distinct mixes of rubber firmness and ceramic depth to maximize performance.

Producers familiar with the industry collaborate closely with plant supervisors to guarantee accuracy and operational suitability.

Manufacturing Excellence & Process Oversight

Precise production and rigorous quality assessments are essential:

- Precise Manufacturing: Tooling, moulding, and tile creation methods ensure uniformity and compliance with design specs.

- Quality Checks: Hardness tests, impact trials, and size verification guarantee consistency from one production run to the next.

- Batch Uniformity: Maintaining consistency across batches is crucial for industrial reliability, reducing variability that could strain equipment.

In demanding industrial settings, reliable manufacturing ensures Combo liners perform as expected throughout their service life.

Fitting & Servicing Aspects

Simplicity in setup and predictable service intervals are primary benefits:

- Simple Assembly: Rubber-backed ceramic liners are designed for bolted fittings, reducing plant shutdown duration.

- Reduced Downtime: Pre-made panels enable quick exchanges, keeping activities running smoothly.

- Service Intervals: Modular designs permit partial renewal, avoiding complete shutdowns and optimizing maintenance planning.

Servicing units often observe that well-conceived combo liners substantially lower both labour and operational interruptions.

Safety & Operational Trustworthiness

Worker well-being and apparatus defence are interconnected:

- Worker Safety: Combo liners lessen noise and vibration, fostering safer work settings.

- Apparatus Defence: Mitigating impact and wear prevents structural strain, safeguarding mills, chutes, and conveyors.

- Plant Dependability: By sustaining steady material flow and reducing unscheduled halts, combo liners increase overall plant uptime.

Fiscal Prudence Over Equipment Lifespan

Long-term industrial planning often prioritizes total lifecycle expenditures over the initial outlay:

- Long-Term Savings: Extended component life due to reduced wear cuts the expense of frequent replacements.

- Fewer Halts: Fewer unplanned stoppages result in higher production yield.

- Servicing Optimization: Modular, robust designs enable planned, scheduled interventions, reducing labour and resource use.

Plant engineers consistently remark that robust wear protection options prove economical over the long haul.

Export Preparedness & Global Acceptance

Producers supplying combo liners for overseas markets must comply with international industry benchmarks:

- International Export Benchmarks: Liners must meet ISO, ASTM, or client-stipulated criteria.

- Paperwork & Standards Awareness: Certifications of material conformity, hardness readings, and dimensional proof are standard prerequisites.

- Worldwide Buyer Demands: Mining ventures in Australia, steel mills in Europe, and ceramic clusters in the Middle East require dependable quality and steady supply.

This worldwide recognition highlights the industrial significance of combo liners beyond domestic uses.

Why Seasoned Producers Matter?

Industrial technicians favour manufacturers who grasp the functional realities of heavy-duty facilities:

- Engineering Acumen: Knowledge of material behaviour, equipment movement, and operational pressures is vital.

- Sector Background: Experienced vendors can foresee wear patterns, material flow snags, and assembly complexities.

- Dependable Supply: Consistent product availability prevents unplanned downtime and supports maintenance scheduling.

Manufacturers with a deep history in the field grasp the subtle points that influence apparatus performance, quality, and plant reliability.

About Kedar Rubber Products

Kedar Rubber Products Pvt Ltd is an experienced manufacturer of industrial wear protection solutions, including ball mill rubber liners, ceramic wear protection tiles, rubber lining systems, conveyor solutions, and combo liners. Serving industrial markets pan India—including Odisha, Jharkhand, Chhattisgarh, Karnataka, Rajasthan, Gujarat, Maharashtra, West Bengal, Tamil Nadu, and Andhra Pradesh—Kedar Rubber Products also supplies global clients in mining, metal, cement, ceramic, and bulk material handling industries. For more details, visit their official website: https://www.kedarrubber.com/.

Conclusion:

In mining and metal processing operations, adequate wear protection is essential for operational efficiency, equipment longevity, and plant safety. Combo Liners combine rubber and ceramic technologies to address abrasion, impact, and corrosion in a single solution. Designed for diverse industrial applications, they reduce maintenance, minimize downtime, and enhance long-term plant reliability.

Plant engineers and maintenance teams benefit from their modularity, adaptability, and precision manufacturing, making combo liners a practical solution for heavy-duty industrial challenges.

Key Takeaways

- Durable wear protection for high-abrasion and high-impact environments

- Enhanced operational reliability and equipment safety

- Suitable for mining, cement, metal & steel, ceramic, and bulk material handling

- An extended lifecycle reduces maintenance interventions

- Globally recognized standards ensure export readiness

FAQS

1. What is the typical lifespan of Combo Liners?

In heavy-duty industrial environments, lifespan depends on material type, operational load, and maintenance frequency. Properly installed combo liners can last multiple years before replacement.

2. Are Combo Liners suitable for all types of ball mills and conveyors?

- Experienced plant engineers often observe that combo liners can be customized for most equipment, including ball mills, chutes, hoppers, and conveyor systems, to ensure optimal fit and performance.

3. How frequently should Combo Liners be inspected or maintained?

- Routine inspection intervals depend on material abrasion levels and impact loads. Monthly visual checks and scheduled maintenance every 6–12 months are typical for heavy-duty operations.

4. Should I choose rubber or ceramic liners?

- Rubber absorbs impact and reduces vibration, while ceramic resists severe abrasion. Combo liners leverage both materials for balanced protection in heavy-duty applications.

#BallMillRubberLiner #CeramicWearProtection #RubberLining #MiningSolutions #ConveyorSolutions #kedarrubberproduct #WearProtection #IndustrialManufacturing