Boosting Ball Mill Performance with Rubber Liners: Kedar Rubber Products

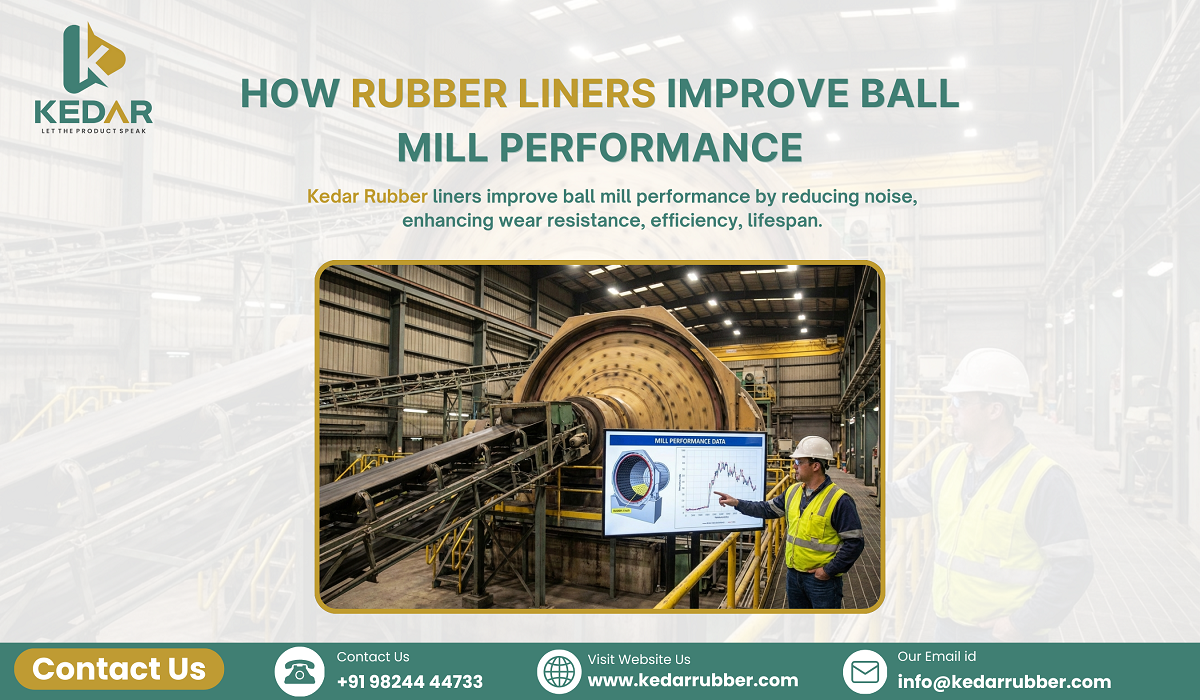

In heavy-duty industrial environments, equipment reliability and operational efficiency are critical factors that determine a plant’s productivity and profitability. Industries such as mining, metal processing, cement manufacturing, ceramics production, and bulk material handling face constant challenges from abrasion, impact, corrosion, and mechanical wear, and even minor equipment downtime can lead to substantial losses in production and operational costs. How Rubber Liners Improve Ball Mill Performance: One effective solution to enhance grinding performance and reduce wear in ball mills is the use of rubber liners. Unlike traditional steel liners, rubber liners absorb impact and dampen vibrations, reducing stress on the mill shell and minimizing mechanical wear.

Industrial Challenges That Drive Demand for Ball Mill Rubber Liners

Industrial operations involve continuous handling of abrasive, corrosive, and heavy materials. In mining and metal processing operations, mills and conveyors are subjected to:

- Abrasion: Continuous grinding of ore, cement clinker, or ceramic raw materials can rapidly wear down equipment surfaces. Rubber and ceramic liners absorb much of this abrasive action, protecting the underlying structure.

- Impact Loads: Heavy materials such as ore chunks or steel billets strike machinery surfaces with high energy. Without adequate protection, repeated impact can crack metal surfaces or cause fatigue failures.

- Corrosion: Certain ores, minerals, and chemical additives can accelerate corrosion, reducing equipment life. Rubber and ceramic coatings provide chemical resistance, safeguarding steel structures.

- Downtime: Equipment failures often lead to unplanned stoppages, affecting production targets. Minimizing downtime is a key driver for adopting high-performance liners.

- Maintenance Costs: Frequent part replacements and repairs can escalate operational costs. Wear protection solutions extend maintenance intervals, reducing overall lifecycle expenses.

Manufacturers with long-term industry exposure understand that selecting the right liner system is not just about material choice but also about precise engineering, application suitability, and installation efficiency.

What Are Ball Mill Rubber Liners?

In industrial terms, Ball Mill Rubber Liners are engineered protective layers installed inside the grinding chamber of ball mills and similar processing equipment. Designed to absorb impact, resist abrasion, and reduce vibration, these liners safeguard the mill’s internal surface while maintaining grinding efficiency.

Unlike steel liners, rubber liners provide shock absorption and reduce noise levels during operation. They are particularly effective in wet or sticky material processing where corrosion and material buildup can otherwise accelerate wear.

Ball mill liners are typically fabricated in modular panels, allowing for easy installation, replacement, and customization based on mill size, operational load, and material characteristics.

Applications Across Industries

- Mining: In iron ore, coal, copper, and other mineral processing operations, ball mill liners are used to protect grinding equipment from heavy ore loads and abrasive fines. Rubber liners absorb impact while reducing wear, extending the lifespan of mills.

- Cement Plants: Cement grinding involves high-speed mills and abrasive clinker. Rubber and ceramic liners protect internal surfaces, reduce downtime, and maintain uniform grinding efficiency.

- Metal & Steel Plants: In secondary steel processing and alloy grinding, liners prevent metal debris from damaging the mill shell, ensuring operational continuity and worker safety.

- Ceramic Manufacturing: Ceramic tiles, sanitary ware, and refractory materials require precision grinding. Rubber and ceramic protection systems reduce chipping and equipment wear while maintaining product quality.

- Power Plants & Bulk Material Handling: Mills and conveyors in coal-fired or biomass plants handle abrasive materials under high load. Rubber liners in feeders, chutes, and conveyors minimize wear, protecting equipment from costly repairs.

Material Science & Engineering Considerations

Understanding the properties of materials used in wear protection is critical for effective design and performance:

- Rubber Properties: High resilience, elasticity, and impact absorption make rubber ideal for milling operations involving high shock and abrasion. Rubber’s chemical resistance also protects against corrosion.

- Ceramic Hardness: Ceramic tiles and liners provide extreme wear resistance and high hardness, suitable for abrasive or erosive materials. They are often combined with rubber for hybrid protection solutions.

- Wear Resistance Principles: Effective liners balance hardness, elasticity, and chemical resistance to optimize both impact absorption and abrasion resistance.

- Impact Absorption: Rubber liners reduce vibration and impact loads on the mill shell, preventing structural fatigue and extending equipment life.

Design & Customization Requirements

Equipment compatibility and operational demands dictate liner design:

- Custom Sizing: Panels and liners are manufactured to match specific mill dimensions, ensuring a snug fit and consistent protection.

- Application-Specific Design: Mining operations may require thicker rubber for high-impact ore, while cement mills may prefer hybrid ceramic-rubber combinations.

- Equipment Compatibility: Mill rotation, grinding media size, and feed material characteristics are considered to prevent operational inefficiencies.

- Experienced plant engineers often observe that tailored designs outperform generic solutions in both protection and operational efficiency.

Manufacturing Quality & Process Control

Ball mill rubber liners require precision manufacturing:

- Precision Manufacturing: Accurate molding and cutting ensure uniform thickness, proper fit, and consistent performance across panels.

- Quality Checks: Rigorous inspection protocols, including hardness, tensile strength, and dimensional accuracy, are critical for reliable performance.

- Batch Consistency: Maintaining uniform material properties across production batches ensures predictable behavior under industrial loads.

Installation & Maintenance Considerations

Proper installation is as important as material quality:

- Ease of Installation: Modular panels simplify installation, reducing mill downtime during maintenance cycles.

- Reduced Downtime: Quick replacement of worn panels ensures continuous operation.

- Maintenance Cycles: Experienced engineers recommend monitoring wear patterns and rotating panels to maximize life span.

Safety & Operational Reliability

Worker safety and plant reliability are enhanced with proper liners:

- Worker Safety: Rubber liners absorb vibration and noise, creating a safer working environment.

- Equipment Protection: Liners prevent structural damage to mills and conveyors, minimizing unexpected breakdowns.

- Plant Reliability: Consistent material flow and reduced wear improve overall plant efficiency.

Export Readiness & Global Acceptance

In international industrial markets, equipment protection solutions must meet strict standards:

- Industrial Export Expectations: Compliance with ISO and ASTM standards ensures global acceptance.

- Documentation & Standards: Technical datasheets, material certifications, and quality reports are critical for export readiness.

- Global Buyer Requirements: Mining and bulk handling companies in Australia, South Africa, Europe, and the Middle East increasingly demand proven wear protection solutions.

Why Experienced Manufacturers Matter?

Manufacturers with deep industry exposure bring critical advantages:

- Engineering Expertise: Knowledge of plant operations informs material selection and design.

- Industry Experience: Years of handling diverse industrial challenges help predict wear patterns and optimize solutions.

- Reliable Supply: Consistent production and delivery schedules prevent operational disruptions.

About Kedar Rubber Products

KEDAR RUBBER PRODUCTS PVT LTD is a trusted industrial manufacturer specializing in:

- Ball Mill Rubber Liners

- Ceramic Wear Protection Solutions

- Rubber Lining Systems

- Conveyor Solutions

- Marine Fenders and Bulk Material Handling Products

Serving Pan India—including mining hubs in Odisha, Jharkhand, Chhattisgarh, and Karnataka; metal clusters in Gujarat, Maharashtra, and Tamil Nadu; cement and ceramic regions across Rajasthan, Andhra Pradesh, and West Bengal—Kedar Rubber Products has earned a reputation for engineering precision, material quality, and reliability. For more details, visit their official website: https://www.kedarrubber.com/.

Conclusion

In mining, metal, cement, and bulk material handling industries, Ball Mill Rubber Liners play a critical role in protecting equipment, enhancing operational efficiency, and reducing maintenance costs. Manufacturers with experience and deep engineering expertise understand that selecting the right liner system is vital for long-term reliability. Properly designed and installed rubber and ceramic protection systems ensure plant safety, consistent material processing, and extended equipment life.

For plant engineers, maintenance teams, and procurement managers, prioritizing high-quality wear protection solutions is an essential step toward sustainable industrial operations.

Key Takeaways

- Effective wear protection improves equipment longevity.

- Rubber and ceramic liners enhance operational reliability.

- Suitable for mining, cement, metal, ceramic, and bulk handling industries.

- Optimized for long-term performance and maintenance efficiency.

- Globally accepted industrial relevance, with export-ready solutions.

FAQs

1. What is the typical lifespan of Ball Mill Rubber Liners?

- Depending on material abrasiveness and operational load, rubber liners can last 2–5 years, while hybrid ceramic-rubber systems may extend service life further.

2. Which industries are best suited for these liners?

- Mining, cement, metal & steel, ceramics, power plants, and bulk material handling operations benefit most from these liners.

3. How frequently should maintenance be performed?

- Experienced plant engineers recommend inspecting liners every 3–6 months, with rotation or replacement as needed based on wear patterns.

4. Rubber vs ceramic wear solutions—what’s the difference?

- Rubber provides impact absorption and chemical resistance, while ceramic offers extreme hardness and abrasion resistance. Hybrid solutions combine both benefits.

#BallMillRubberLiner #CeramicWearProtection #RubberLining #MiningSolutions #BulkMaterialHandling #ConveyorSolutions #kedarrubberproduct #WearProtection #IndustrialManufacturing