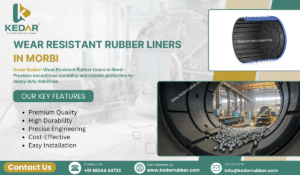

Kedar Rubber Products: Wear-Resistant Rubber Liners in Morbi to Boost Equipment Longevity

Industries such as mining, metal refining, cement production, ceramics, and bulk goods handling are subject to some of the toughest mechanical stresses. Equipment is constantly exposed to grinding minerals, sharp objects, repeated blows, moisture, and chemical contact, all while running nonstop. In these intense settings, component wear is unavoidable. This is why Wear Resistant Rubber Liners in Morbi are vital: they offer excellent shielding, reduce service interruptions, and help key industrial machinery last longer.

For plant managers and maintenance crews, the genuine hurdle isn’t whether wear occurs, but how reliably and cost-effectively it can be managed. Unexpected shutdowns, line breaks, product loss, and frequent repairs directly impact output goals, safety, and operating expenses.

Around the world, sectors are turning to specialized wear-defense systems that boost equipment reliability without complicating workflows. Among these solutions, Wear-Resistant Rubber Liners have become a key part of extending useful life while keeping steady operations. Their ability to absorb impact, withstand wear, and reduce maintenance frequency makes them a smart pick for rugged industrial use.

Industrial Hurdles Driving the Need for Wear-Resistant Rubber Liners

In demanding industrial settings, the ways things wear down are seldom separate issues. Most machinery experiences a mix of forces that speed up deterioration.

- Abrasion: Continuous contact with rock, cement dust, coal, ceramic feedstocks, or stored materials scrapes away surfaces in chutes, grinders, bins, and conveyors.

- Impact Forces: Large particle sizes and long drops in mining and bulk transport systems generate repeated shock waves that crack rigid linings and damage the steel beneath.

- Corrosion and Chemical Contact: Moisture, wet mixtures, and process chemicals create environments that erode standard metal linings over time.

- Pressure from Outages: Unscheduled lining swaps lead to lost production, especially in continuous operations like cement, power, and steel mills.

- Rising Maintenance Costs: More frequent lining changes increase labor hours, spare parts stock, and safety risks during downtime.

These difficulties are common in mining areas globally, metal processing centers, ceramic clusters, and large infrastructure-linked industrial markets. As a result, sectors seek wear protection solutions that balance durability with operational flexibility.

What Are Wear-Resistant Rubber Liners?

Wear-resistant rubber Liners are specially designed protective surfaces that shield equipment interiors from damage caused by friction, impact, and material passage. Unlike hard linings, rubber linings absorb energy rather than just resisting it through stiffness.

From a technical viewpoint, these linings are created using particular rubber mixes optimized for:

- Resistance to rubbing

- Ability to spring back

- Strength against tearing

- Controlled firmness

They are frequently used on their own or paired with ceramic wear pieces in zones subject to extreme rubbing.

It’s important to note that rubber linings aren’t a universal fix. How well they work depends on the rubber blend chosen, the liner’s thickness, how it’s attached, and its compatibility with the host machine.

Uses Across Different Sectors

- Mining: In extraction and metal refining work, rubber linings are widely fitted in rod/ball mills, slurry pipes, hoppers, transfer chutes, and screening gear—their shock absorption helps protect equipment during handling of large, irregularly shaped ores.

- Cement Plants: Cement making involves continuously moving clinker, limestone, and additives. Rubber linings are installed in chutes, storage silos, cyclones, and mills to manage abrasive flow and reduce structural wear.

- Metal & Steel Factories: Steel mills employ rubber lining systems for handling raw materials, in sinter plants, and in areas dealing with waste slurry where rubbing and moisture are present.

- Ceramic Making: Feedstocks for ceramics are very abrasive. Rubber linings, often integrated with ceramic wear wafers, are used in mills and transport systems to manage wear without compromising material purity.

- Power Plants: Coal-handling setups in thermal power stations depend on rubber linings for conveyors, storage bunkers, and transfer points to minimize wear and maintenance associated with dust.

- Bulk Material Movement: Ports, storage depots, and processing sites handling gravel, fertilizers, and minerals use rubber linings to improve flow efficiency and lessen damage from spills.

Material Science & Engineering Aspects

Seasoned plant engineers often see that lining failure seldom stems from just rubbing. It’s the interplay between the material’s makeup and its use that determines how long the lining lasts.

- Rubber Qualities: Key attributes include stretching potential, breaking resistance, and hardness. Softer blends handle impact better, while firmer blends offer superior abrasion resistance.

- Ceramic Blending: In areas of high abrasion, ceramic discs set into a rubber base combine hardness with impact dampening. This blended method reduces tile breaking compared to ceramic-only linings.

- Wear Reduction Concepts: Rubber linings reduce wear by reducing direct contact between metal and material and by quieting vibrations, thereby safeguarding nearby structures.

- Impact Cushioning: Elastic stretching when under load stops stress from concentrating, a frequent source of fatigue cracks in rigid linings.

Design & Customization Needs

Effective wear defense relies on how seamlessly the lining fits the equipment.

- Equipment shape and how it must be fixed in place

- Tailored sizing for mills, chutes, and bins

- Lining designs that bolt on, are glued, or are modular

- How materials move and where impacts are focused

Manufacturers with deep industry background know that a poorly designed lining can cause material blockage, restricted flow, or uneven wear—wiping out any performance benefits.

Manufacturing Excellence & Process Checks

High manufacturing standards directly impact how reliably the lining performs.

- Controlled rubber mix formulation

- Precise shaping and curing processes

- Checks for exact measurements

- Tracking of materials by production batch

Process control ensures every liner behaves as expected under industrial strain, rather than relying solely on theoretical material specifications.

Setup & Servicing Notes

From a maintenance angle, rubber linings bring practical upsides:

- Quicker setup time compared to heavy steel linings

- Lower risk during movement because of lighter weight

- Simpler swaps during scheduled plant breaks

Maintenance periods are easier to plan, allowing teams to align line replacements with planned outages rather than emergency stops.

Safety & Operational Dependability

Safety is a prime concern during the fitting and changing of linings.

Rubber linings help lower:

- Injuries from manual lifting

- Exposure to sharp edges

- Structural harm resulting from lining failure

By shielding equipment surfaces, they also help keep alignment and operational stability, adding to overall plant trustworthiness.

Cost Effectiveness Across the Equipment Lifespan

Instead of focusing solely on the initial cost of a liner, operations assess its performance throughout its working life.

- Longer time between service replacements

- Less frequent need for shutdowns

- Reduced secondary harm to machinery

Over time, predictable linear performance helps optimize maintenance and steady production scheduling without unforeseen interruptions.

Preparedness for Export & Worldwide Acceptance

International industrial purchasers anticipate:

- Proof of material quality

- Necessary quality paperwork

- Uniform production standards

Wear defense systems must be adequate for various working environments found in mining centers, ceramics facilities, and metalworking sectors globally. Manufacturers ready for export possess knowledge of the crucial compliance, packaging, and documentation needs for international shipments.

The Value of Experienced Producers

Wear protection is an engineering specialty, not merely a standard product.

Producers with experience offer:

- Advice tailored to the specific application

- Material mixtures that have been tested

- Consistent availability of supplies

Their understanding of real-world plant scenarios helps avoid costly installation guesswork.

About KEDAR RUBBER PRODUCTS PVT LTD

KEDAR RUBBER PRODUCTS PVT LTD is an established maker of durable rubber liners, ceramic wear defense options, rubber lining setups, ball mill rubber components, and conveyor systems. Serving all major central locations across India, the firm supports sectors ranging from resource extraction and cement to ceramics and bulk-material handling, while also serving worldwide industrial markets.

Further details can be found at 👉 https://www.kedarrubber.com/

Summary

Wear-Resistant rubber Liners play a crucial role in shielding essential industrial machinery from wear caused by rubbing, forceful blows, and operational strain. When designed and installed appropriately, they enhance facility reliability, support more effective maintenance planning, and improve long-term operational efficiency.

For industries operating under severe conditions, selecting the best liner option—and the right manufacturing partner—remains a vital element in maintaining output performance.

Main Points to Remember

- Rubber liners effectively manage both abrasion and impact

- Enhanced equipment dependability and security

- Applicable across mining, cement, metal, ceramic, and power sectors

- Aids in improving maintenance processes

- Proven utility in worldwide industrial activities

Current Frequently Asked Questions

1. What is the typical operating period for wear-resistant rubber liners?

Their longevity varies depending on the material processed, the impact force, and the operating environment. Well-designed liners provide reliable service intervals.

2. Can rubber liners handle high-impact uses?

Yes. Rubber’s flexible nature makes it effective at absorbing repetitive impact forces.

3. How often do rubber liners need upkeep?

They require less frequent maintenance compared to hard liners, particularly in areas with significant impact.

4. How to decide between rubber and ceramic wear solutions?

Rubber is preferred where absorbing impacts is key, while rubber liners backed with ceramic are better suited for areas with extreme wear from rubbing.

5. Are these liners utilized internationally?

Yes. They are widely used in the mining, cement, steel, and bulk-handling industries worldwide.

#WearResistantRubberLiners #BallMillRubberLiner #RubberLiningSystems #CeramicWearProtection #CeramicWearTiles #MiningWearSolutions #IndustrialRubberProducts #BulkMaterialHandling #ConveyorSolutions