Kedar Rubber Products: Advanced Manufacturing by Fixing Hardware Manufacturer in Ahmedabad

In heavy-duty industrial environments, equipment reliability and superior wear resistance are essential to sustained operational efficiency. Advanced Manufacturing by Fixing Hardware Manufacturer Experts ensures that critical components perform consistently under extreme conditions. Industries such as mining, metal processing, cement, and ceramic manufacturing operate amidst abrasive materials, high-impact loads, and continuous production cycles. For plant engineers and maintenance teams, preventing downtime caused by worn components, unplanned shutdowns, or hardware failure is vital, as these issues directly affect productivity, safety, and operating costs.

Current industrial demand patterns reveal a growing need for robust, finely calibrated wear protection systems. Across diverse sectors, from mineral extraction sites in Odisha and Jharkhand to the pottery production centers of Morbi, Gujarat, and cement facilities throughout Rajasthan and Andhra Pradesh, enterprises are actively allocating funds toward methods that lessen deterioration and prolong machinery service life. Within this context, Fastening Components play a vital role in securely holding rubber sheets, ceramic components, and other wear-mitigation systems in place—ensuring sustained reliability, peak plant output, and shorter maintenance schedules.

Operational Hurdles Fueling Fastener Demand

Intense facility operations confront numerous difficulties that directly impact machinery functionality:

- Surface Wear: The constant movement of material, particularly in resource extraction and cement production, wears down equipment surfaces. Rubber coverings and ceramic panels depend on secure fastening hardware to stop movement under high-friction conditions.

- Impact Forces: In grinding units and bulk material transport lines, items drop from considerable elevations. The securing hardware ensures the protective veneers withstand recurring impacts without loosening.

- Deterioration: Chemical reactions in metal fabrication, energy plants, and specific ceramic procedures can degrade unsecured machinery elements. Premium fastening accessories resist breakdown and sustain structural soundness.

- Stoppages & Service Expenses: Unforeseen shutdowns caused by degraded or dislodged panels increase repair costs. Seasoned facility supervisors frequently note that proper hardware deployment reduces standstill time and extends equipment lifespan.

- Global Industrial Settings: Throughout major industrial zones in India and internationally—including extractive regions in Australia, metal processing units in Europe, and cement complexes in the Middle East—dependable fastening apparatus is essential for maintaining consistent site performance.

In material extraction and metal refining activities, the failure of even minor hardware components can trigger cascading negative impacts on site efficiency, personnel welfare, and operating expenses.

What Constitutes Fastening Hardware?

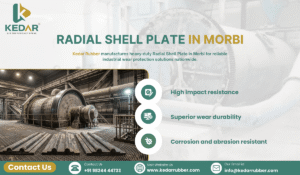

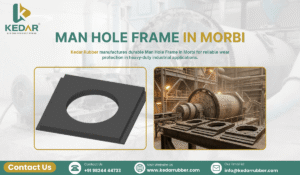

Fastening hardware comprises specially designed components used to affix protective wear provisions—such as ball mill rubber linings, ceramic plating, and rubber sheeting systems—to industrial machinery. This hardware generally comprises bolts, fixings, studs, and anchoring mechanisms, engineered to endure severe surface wear, forceful impacts, and temperature variations.

Unlike routine fastening hardware, industrial fastening hardware is manufactured to precise tolerances and material specifications to maintain the integrity of the lining in high-stress applications. Producers with extensive industry background realize that a poorly positioned or brittle fastening configuration can result in premature lining failure, material escape, and unscheduled facility downtime.

Uses Across Different Sectors

- Mining: In heavy-duty grinding mills and conveyor systems, the securing hardware holds rubber and ceramic panels against high-impact ore and abrasive mass. Mining endeavors in Odisha, Jharkhand, Chhattisgarh, and Rajasthan rely on precisely manufactured equipment to sustain continuous output and minimize maintenance frequency.

- Cement Plants: Equipment within kilns and mills necessitates liners and protective plating to withstand the abrasive grind of clinker and raw feedstock. The fastening mechanisms ensure firm seating of these panels, safeguard machinery, and limit unforeseen shutdowns across facilities in Andhra Pradesh, Gujarat, and Maharashtra.

- Metal & Steel: Steelworks and foundries expose conveyors and grinding apparatus to intense surface attrition and heat stress. Fastening hardware in these settings supports ceramic protective chips and rubber sheeting, helping prevent process interruptions in hot, abrasive environments.

- Ceramic Fabrication: In zones producing ceramic tile and sanitary ware, such as Morbi, Gujarat, and Khurja, Uttar Pradesh, the fixings ensure the durability of wear-resistant linings that handle abrasive raw materials like clay and frit.

- Power Generation & Bulk Material Conveyance: Coal pulverizers, fly ash transporters, and bulk material handling setups endure significant surface erosion. Fastening hardware ensures rubber sheathing and ceramic tiles remain intact, boosting operational reliability and employee safety.

Material Science & Engineering Factors

The efficacy of the fastening hardware hinges on understanding the material science underpinning wear defense provisions:

- Rubber Characteristics: Commercial-grade rubber liners cushion impacts, dampen sound, and resist surface wear. The accompanying hardware must permit suitable compression without distortion.

- Ceramic Rigidity: Ceramic components deliver superior wear resistance but are fragile. The securing hardware must account for thermal expansion and absorb shock to prevent panel fracturing.

- Wear Resistance Concepts: Accurate hardware arrangement ensures even panel contact, lessening localized wear and prolonging operational lifespan.

- Impact Damping: In heavily loaded mills, the hardware must resist loosening under repeated shocks. Designers evaluate bolt strength, spacing, and the distribution of reinforcing plates to optimize load transmission.

Design & Customization Needs

Fastening hardware is not universally standardized. Design factors to consider include:

- Machine Compatibility: The hardware must align with the machine’s structure, the thickness of the lining panel, and the wear profile.

- Bespoke Sizing: Mills, conveyor belts, and receiving bins frequently necessitate customized hardware dimensions for optimal panel interface.

- Application-Specific Blueprint: Engineers choose materials—like stainless alloys, specialized fasteners, or coated parts—based on the demands of corrosion, heat, and impact.

Seasoned facility managers often observe that bespoke hardware design significantly enhances panel performance and reduces maintenance frequency.

Production Quality & Process Oversight

Precise manufacturing and rigorous quality checks are vital for producing fastening hardware:

- Precision Fabrication: Computer-controlled machining, thread cutting, and thermal conditioning ensure that hardware dimensions meet industrial benchmarks.

- Quality Verification: Each production lot undergoes dimensional review, material assessment, and corrosion resistance testing.

- Lot Uniformity: Standardized output guarantees replacement hardware matches existing installations, minimizing delays during service operations.

Mounting & Service Considerations

Correct setup is crucial for performance and well-being:

- Mounting Simplicity: Hardware designs include self-leveling studs and washers for quicker, more secure attachment.

- Reduced Standstill: Fast and precise installation minimizes interruptions to production.

- Service Intervals: Superior fastening hardware extends panel life, reducing the need for frequent exchanges and service interventions.

Safety & Operational Dependability

The securing hardware directly supports site wellbeing and reliability:

- Personnel Safety: Firmly attached panels prevent falling fragments, lowering accident hazards.

- Equipment Safeguarding: Appropriately fixed panels absorb wear and force, shielding machinery from structural damage.

- Site Reliability: Stable panels maintain efficient material flow, reducing interruptions in demanding processes.

Fiscal Efficiency Across the Equipment Lifecycle

Committing to durable fastening hardware delivers enduring operational advantages:

- Long-Term Savings: Lowering the frequency of panel replacements and extending machinery lifespans reduces running costs.

- Fewer Disruptions: Attaining fewer unscheduled stoppages boosts overall site productivity.

- Maintenance Streamlining: Standardized hardware lessens labor input and the complexity of managing spare part inventories.

Export Readiness & International Acceptance

Industrial producers are increasingly adhering to international benchmarks for worldwide markets:

- Export Benchmarks: Conformance to ISO, ASTM, and DIN norms certifies the hardware’s suitability for overseas setups.

- Documentation & Standards Awareness: Quality confirmations, material evaluation reports, and setup guides aid in international purchasing.

- Global Client Demands: Extracting hubs in Australia, manufacturing sectors in Europe, and cement facilities in the Middle East often stipulate certified, premium fastening hardware.

Why Seasoned Producers Are Important?

Manufacturers with extensive time in the field grasp the subtle requirements of industrial wear mitigation:

- Engineering Acumen: Knowledge of how materials behave under friction and impact ensures optimal hardware layout.

- Sectoral Background: Familiarity with operational hurdles across resource extraction, cement, steel, and ceramics informs the development of dependable remedies.

- Reliable Supply Lines: Steady manufacturing schedules prevent unplanned facility shutdowns, which are critical for large-scale industrial activities.

About KEDAR RUBBER PRODUCTS PVT LTD

KEDAR RUBBER PRODUCTS PVT LTD stands as a primary manufacturer of industrial wear defense provisions, including ball mill rubber liners, ceramic wear defense tiles, rubber lining systems, and conveyor options. Serving facilities across India—from Rajasthan, Maharashtra, Gujarat, Andhra Pradesh, Tamil Nadu, Karnataka, Chhattisgarh, Odisha, Jharkhand, and Uttar Pradesh—to international industrial arenas, KEDAR RUBBER PRODUCTS assures high-grade, engineered solutions.

Investigate their expertise at 👉 https://www.kedarrubber.com/.

In Summary:

In the mining, metal refining, cement, and ceramic sectors, Fastening Hardware is more than just a simple connector—it is a vital element that ensures the resilience and reliability of wear protection systems. From curtailing unexpected standstills to boosting safety and optimizing maintenance, properly designed and manufactured hardware plays a central role in industrial productivity. Experienced engineers and facility supervisors acknowledge that investing in high-quality fastening hardware yields measurable improvements in operational capability.

Key Insights

- Wearing protective measures prolongs equipment operating duration.

- Appropriate hardware ensures stable operation in demanding environments.

- Applicable across mining, cement, metalwork, ceramics, and bulk handling industries.

- Sustained performance reduces upkeep cycles and operational breaks.

- Solutions are relevant to both Indian and global industrial markets.

FAQS

1. What is the typical lifespan of fixing hardware in ball mills and conveyors?

- In heavy-duty industrial environments, fixing hardware can last 3–5 years under normal conditions, though lifespan varies with material abrasiveness and operational loads.

2. Are the fixing hardware components suitable for high-temperature cement plant operations?

- Yes, with proper material selection, hardware withstands elevated temperatures and maintains secure liner attachment.

3. How often should the hardware be inspected or maintained?

- Experienced plant engineers often recommend quarterly inspection cycles, with more frequent checks in high-wear zones.

4. When should rubber liners be used versus ceramic tiles?

- Rubber absorbs impact and reduces noise, making it ideal for high-impact, low-abrasion applications. Ceramic offers extreme wear resistance in abrasive environments.

#BallMillRubberLiner #CeramicWearProtection #RubberLining #MiningSolutions #BulkMaterialHandling #ConveyorSolutions #kedarrubberproduct #WearProtection #IndustrialManufacturing