Filler Block in Morbi: A Critical Wear Protection Component for Demanding Industrial Operations

In demanding industrial settings, machinery endures relentless surface wear, heavy impacts, chemical attack, and varying operational demands. Mining deals with gritty ores, cement facilities process scorching clinker, and ceramic production involves handling jagged feedstock. Within industrial centres such as Morbi, where ceramic manufacturing and handling of large volumes of material occur constantly, Filler Block in Morbi serve to protect equipment crevices, mitigate concentrated wear, and support dependable, extended plant functioning with fewer service interruptions.

Unexpected stoppages brought on by wear failures remain a major headache for plant supervisors and maintenance crews. As worldwide industrial needs keep growing—fueled by infrastructure build-outs, energy initiatives, and mineral refinement—plants face heightened pressure to maximise equipment lifespan while sustaining steady output.

Against this backdrop, Wear Guard Insert systems have surfaced as a key defence against wear. Although sometimes overlooked, these inserts play a crucial role in sealing openings, shielding structural elements, and ensuring even load-bearing in equipment susceptible to wear. Their actual value emerges when viewed in terms of durable equipment reliability rather than quick fixes.

Industrial Hurdles Driving Need for Wear Guard Inserts

- Surface Erosion: In mining and metal refining, the continuous movement of material causes surface attrition. Sharp particles rub against equipment linings, especially at transfer points, seams, and corners where standard liners might not fully cover exposed areas.

- Impact Forces: Experienced plant operators often note that impact damage leads to more frequent breakdowns than abrasion alone. Sudden material drops create localised stress areas, leading to fractures, liner detachment, or structural weakening.

- Chemical Degradation: Exposure to chemicals, moisture, and process liquids hastens material deterioration, particularly in power stations, fertiliser plants, and mineral processing sites.

- Outages: Even small wear openings can spiral into significant shutdowns if not addressed promptly. Equipment halts upset production timelines and raises operational hazards.

- Service Expenses: Recurring temporary fixes and urgent call-outs substantially increase upkeep costs over the equipment’s active life.

Across the globe, industrial sites are moving towards comprehensive wear protection strategies that eliminate weak spots rather than reacting after damage occurs. Wear guard inserts target these very neglected zones.

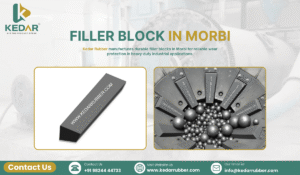

What Is a Filler Block?

A Filler Block is a specifically engineered component designed to fill spaces between liners, framework sections, or equipment boundaries. Such gaps commonly arise from intricate equipment shapes, heat-induced expansion, or installation variances.

Instead of acting as the main protective layer, a wear guard insert functions as a safeguarding layer that:

- Keeps material from entering hidden spaces

- Spreads out impacts and loads uniformly

- Defends equipment edges and secures hardware

- Improves the overall efficiency of the lining arrangement

Wear guard inserts are typically made from rubber, tough rubber-ceramic blends, or flexible polymer materials, depending on the specific task. Their function is proactive, not reactive.

Applications Across Sectors

- Mining: Utilised in chutes, bins, grinding equipment, and material transfer zones to stop material buildup and shield structural steel from rubbing and impacts.

- Cement Processing: Deployed in clinker conveyance systems, pre-heater towers, and material transfer spots where fine abrasive particles accelerate wear.

- Metal & Steel Works: Fitted in sintering units, coke handling areas, and conveyor transfer points to guard against forcefully impacting metallic substances.

- Ceramic Production: Essential in raw material preparation and liquid handling zones where sharp ceramic fragments cause rapid surface breakdown.

- Power Generation: Used in coal handling setups, ash transfer lines, and storage hoppers to lessen erosion and the risk of leaks.

- Bulk Material Movement: Effective at ports, storage facilities, and processing centres where conveyors and chutes operate constantly under load.

Material Science & Design Principles

The effectiveness of a wear guard insert heavily relies on material choice and engineering construction.

- Rubber Characteristics: Rubber provides superior shock dampening, pliability, and vibration isolation. Its elasticity allows it to compress under stress and return to form without cracking.

- Ceramic Resilience: Ceramic sections offer exceptional abrasion resistance. When paired with rubber, the ceramics manage sliding wear while the rubber absorbs impact energy.

- Wear Resistance Concepts: Wear is not uniform. Areas subject to sliding friction require hardness, whereas areas subjected to jolts need flexibility. Hybrid insert designs strike a balance between both.

An engineering-focused approach considers particle size, impact speed, dampness, and operational heat before selecting materials.

Design & Customisation Needs

Wear guard inserts are seldom off-the-shelf items.

- Equipment Conformity: Each insert must precisely match the equipment’s contours to prevent localised stress points or misalignment.

- Bespoke Sizing: Custom-formed or precisely cut inserts guarantee a snug fit, preventing gaps where material could gather.

- Task-Specific Design: Design specifications vary significantly between a grinding mill, a conveyor trough, and a cyclone separator. Universal solutions often prove inadequate in practice.

Manufacturers with deep industry tenure recognise that customisation isn’t an option—it’s a necessity.

Manufacturing Excellence & Process Control

Precise fabrication directly influences the performance of wear guard inserts.

- Controlled rubber mixing ensures stable flexibility.

- Accurate moulding avoids size deviations

- Bonding integrity of ceramic elements is vital for composite types

- Checks performed on each batch sustain consistency across installations

Rigorous adherence to the process ensures that wear guard inserts behave as expected under industrial conditions.

Fitting & Servicing Guidelines

- Simplicity of Installation: Well-conceived wear guard inserts shorten installation time and reduce the need for on-site adjustments.

- Minimised Downtime: A precise fit prevents premature failures, extending service intervals.

- Service Intervals: Wear guard inserts are often replaced during scheduled maintenance, reducing the need for emergency repairs.

Ease of fitting directly contributes to better operational efficiency.

Safety & Operational Dependability

Unsecured debris, liner degradation, and exposed structural elements present significant hazards.

- Filler blocks mitigate risks from falling objects

- Safeguard fixings and structural frameworks

- Enhance overall machinery steadiness

By addressing susceptible areas, facilities achieve safer work environments and more predictable performance.

Economic Value Across Equipment Lifespan

Though filler blocks are minor parts, their effect over time is considerable.

- Lessened liner deterioration

- Fewer operational halts

- Reduced labour input for upkeep

- Prolonged equipment service duration

Fiscal soundness is realised through consistent performance, not just an initial low expense.

International Market Readiness & Global Acceptance

Purchasers in global industries anticipate:

- Uniform quality standards

- Technical specifications

- Material lineage verification

- Adherence awareness to worldwide norms

Filler block designs focused on export readiness are gaining broader acceptance worldwide across the mining, cement, and metal processing sectors.

The Value of Seasoned Producers

Managing wear is more than selecting materials; it involves grasping how plants truly operate.

Experienced manufacturers contribute:

- In-depth process understanding

- Proficiency in failure diagnosis

- Stable material sourcing channels

- Insights into lasting performance metrics

This background minimises trial-and-error exposure for end clients.

Regarding KEDAR RUBBER PRODUCTS PVT LTD

KEDAR RUBBER PRODUCTS PVT LTD is an established industrial producer focusing on rubber wear countermeasures, ceramic wear defence assemblies, rubber cladding installations, rubber items for grinding mills, and conveying systems. Serving industrial clients across India—including major industrial regions like Maharashtra, Gujarat, Rajasthan, Odisha, Jharkhand, Chhattisgarh, Karnataka, Tamil Nadu, Andhra Pradesh, Telangana, West Bengal, Madhya Pradesh, Uttar Pradesh, Punjab, Haryana, and other key states—the firm supports the mining, cement, metal, ceramic, and bulk material handling sectors with custom-engineered wear mitigation solutions.

Further data can be found at 👉 https://www.kedarrubber.com/

Summary

Filler Block arrangements serve a vital yet frequently overlooked position in industrial wear defence strategies. By filling voids, cushioning shock, and shielding sensitive machinery zones, they directly boost facility efficiency, safety, and dependability.

For industries facing constant wear challenges, thoughtful inclusion of filler blocks is a sensible step toward sustained operational stability.

Key Points

- Shields equipment gaps from wear and impact stress

- Boosts operational trust and workplace security

- Applicable across mining, cement, metal, and bulk transport sectors

- Aids sustained equipment output

- Necessary for both local and international industrial activities

Frequently Asked Questions (Trending)

1. What is the typical service duration for a filler block?

Its duration depends on the chosen material, the operating environment, and the intensity of impacts.

2. Are filler blocks suitable for areas with heavy impact?

Yes, provided they are engineered using suitable rubber or composite compounds.

3. How often should filler blocks be checked?

They are generally inspected during scheduled downtimes and swapped out as necessary.

4. Rubber versus ceramic filler blocks—what distinguishes them?

Rubber dampens physical shock; ceramic resists surface erosion. Hybrid types integrate both properties.

5. Do mining and cement facilities internationally utilise filler blocks?

Indeed, they are widely employed in wear protection systems worldwide.

#FillerBlock #BallMillRubberProducts #RubberWearSolutions #CeramicWearProtection #RubberLiningSystems #MiningWearProtection #CementPlantSolutions #SteelPlantWearParts #BulkMaterialHandling #ConveyorWearSolutions #KedarRubberProducts