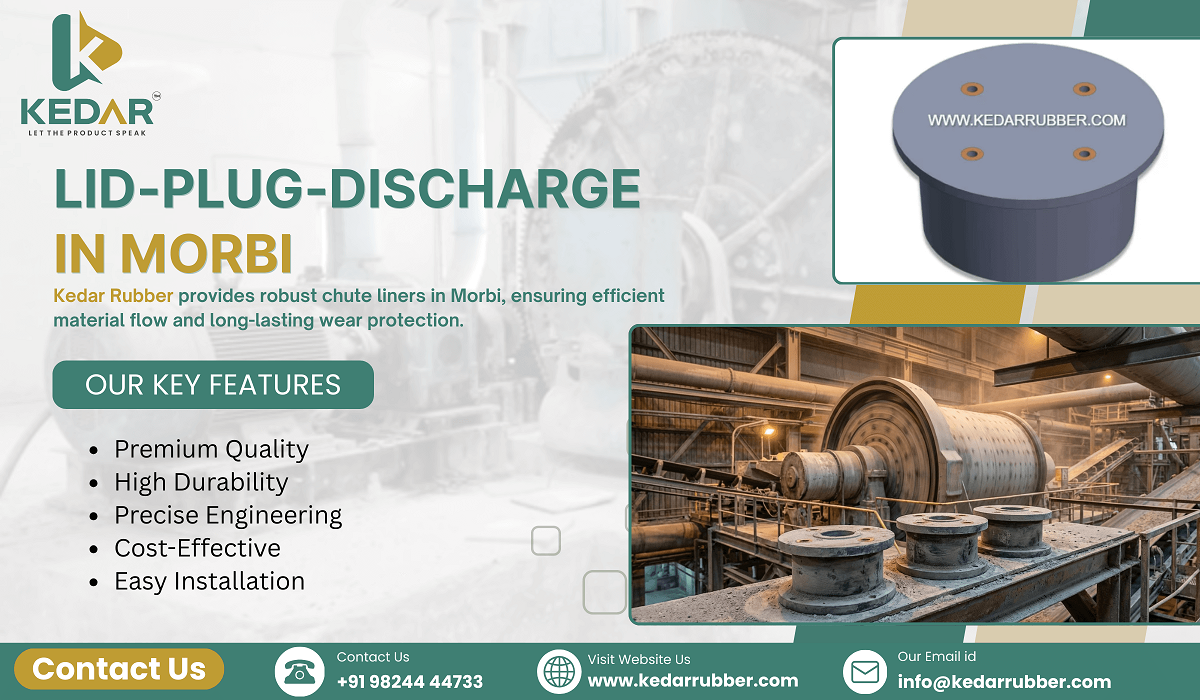

Lid-Plug-Discharge in Morbi: A Critical Component for Industrial Wear Protection

In demanding sectors such as mining, metal fabrication, cement production, and ceramics, machinery endures severe abrasion, heavy blows, and corrosive environments, leading to stoppages and costly maintenance. Solutions like the Lid-Plug-Discharge in Morbi deliver tough, wear-resistant operation, ensuring smooth material flow and reducing equipment wear. By adopting these superior parts, facility supervisors can prolong machinery lifespan, reduce maintenance, and improve operational efficiency. Opting for dependable discharge mechanisms enhances output, curbs unexpected halts, and maximizes lasting profitability.

Globally, there’s an increasing need for reliable, abrasion-resistant parts that can withstand harsh conditions. From this viewpoint, the Lid-Plug-Discharge has emerged as a vital solution for improving operational efficiency and machine reliability. Tailored for rigorous industrial use, this element plays a key role in lessening wear and tear on heavily stressed gear.

Industrial Hurdles Fueling the Need for Lid-Plug-Discharge

Facilities in mining, cement, metallurgy, and ceramics encounter several operational difficulties:

- Friction: Constant handling of hard, rough materials like ores, clinker, and metal waste causes considerable surface wear on machinery. Parts like discharge arrangements are particularly susceptible.

- Impact Forces: Dropping material from heights and flow patterns create repeated shock waves, leading to strain in unprotected sections.

- Deterioration: Contact with moisture, chemical additives, or industrial residues speeds up decay, particularly in metal parts.

- Production Halts: Unscheduled servicing due to damaged discharge pieces disrupts production plans and increases operating expenses.

- Repair Outlays: The constant need to replace poorly shielded components leads to high recurring expenditures, particularly at large-scale industrial sites across cities such as Jamshedpur (Jharkhand), Bhilai (Chhattisgarh), Durgapur (West Bengal), and Ahmedabad (Gujarat).

Seasoned plant engineers frequently note that incorporating robust wear-defence systems, such as the Lid-Plug-Discharge, reduces both outage periods and replacement frequency, ultimately improving long-term plant performance.

Defining the Lid-Plug-Discharge

The Lid-Plug-Discharge is a purpose-built part intended to shield high-contact areas in material outlet systems. Unlike standard wear components, it integrates shock absorption, abrasion resistance, and chemical stability into a single unit.

Practically speaking, it functions as a stopper or cover assembly within exit chutes, bins, or grinding machines, ensuring bulk material exits equipment efficiently without unnecessarily damaging key metal surfaces. Its design addresses the ongoing problem of material-induced degradation while enabling fluid operational movement.

In mining and metal processing, its significance is paramount: even slight degradation at outlet points can cascade into major plant inefficiencies.

Uses Across Various Sectors

Mining

In mining operations across Rajasthan, Madhya Pradesh, and Odisha, ore-handling equipment undergoes intense wear. Lid-Plug-Discharge units shield ball mills and conveyor belts by mitigating wear from high-force, coarse ores.

Cement

Cement production sites in Chhattisgarh, Telangana, and Maharashtra manage highly abrasive clinker and raw material streams. Fitting resilient discharge parts ensures continuous material transport, reducing the likelihood of sudden repair needs.

Metal & Steel

Steel mills in Jharkhand, West Bengal, and Odisha process heavy scrap and iron ore. Employing robust discharge systems for wear defence prolongs the life of vital gear, including hoppers and mills.

Ceramic

Ceramic makers in Gujarat and Rajasthan handle abrasive fine powders. The [Lid-Plug-Discharge] protects equipment surfaces, maintaining steady product quality and shorter downtime.

Power Generation

Coal-fired power plants in Madhya Pradesh and Maharashtra benefit from wear-resistant discharge systems to manage high-volume coal flows effectively.

Bulk Material Transit

Logistics hubs within India’s industrial corridors rely on robust discharge equipment to ensure the seamless transfer of granular materials, fertilizers, and other bulk goods, minimizing operational interruptions.

Material Science & Engineering Insights

Understanding the materials and engineering concepts behind the Lid-Plug-Discharge is vital for facility engineers:

- Rubber Qualities: Premium industrial rubber offers pliability and impact dampening. Its elasticity reduces stress on metal frameworks.

- Ceramic Strength: Ceramic inlays offer superb abrasion resistance. Their toughness ensures minimal wear in high-force discharge zones.

- Wear Resistance Concepts: The blend of rubber and ceramic enables strategic placement of each material to meet specific friction and impact demands.

- Shock Mitigation: Industrial-grade rubber layering disperses kinetic energy, safeguarding both machinery and personnel from wear-related failures.

Producers with extensive sector experience recognize that selecting the appropriate material mix for the operational setting is key to maximizing the component’s service duration.

Design & Customization Requirements

- Machine Suitability: Lid-Plug-Discharge elements must be precisely manufactured to integrate with specific mill, conveyor, or bin configurations.

- Bespoke Sizing: Every industrial setup requires unique plug dimensions, lengths, and profiles for optimal performance.

- Context-Specific Design: Mining tasks might necessitate thicker ceramic layers, whereas cement and general material handling benefit from more adaptable rubber liners to absorb recurrent shocks.

Seasoned plant engineers often stress that tailored components outperform standard alternatives in strenuous industrial settings.

Manufacturing Excellence & Process Oversight

Precise production is fundamental to industrial dependability:

- Accuracy in Dimensions: Components are manufactured to exact tolerances to ensure a tight fit.

- Performance Verification: Every lot undergoes thorough testing for hardness, rub resistance, and chemical compatibility.

- Uniformity Between Batches: Consistent operation across production runs ensures predictable servicing schedules and operational assurance.

KEDAR RUBBER PRODUCTS PVT LTD adheres to strict process controls to uphold elevated standards for every Lid-Plug-Discharge unit.

Fitting & Servicing Notes

Simplicity of setup offers a significant operational advantage:

- Decreased Outages: Parts can be mounted swiftly without lengthy facility stoppages.

- Servicing Intervals: Routine checks and standard upkeep extend the functional life of both the Lid-Plug-Discharge and linked machinery.

- Simplified Swaps: Modular designs permit fast exchanges, minimizing disruption to production timetables.

Safety & Operational Dependability

Thoughtfully designed wear elements directly impact personnel’s well-being and plant soundness:

- Personnel Safety: Appropriately designed discharge parts reduce the likelihood of unintended material expulsion or mechanical failure.

- Equipment Safeguarding: Shielding vital machinery reduces failures stemming from wear and costly repairs.

- Plant Uptime: Consistent output guarantees continuous manufacturing, a primary indicator for industrial endeavours.

Cost Effectiveness Throughout Equipment Lifespan

While the initial outlay for wear-resistant parts might seem considerable, the lifelong advantages are substantial:

- Ongoing Savings: Less frequent replacement means lower running expenditures.

- Minimized Stoppages: Reduced downtime boosts overall production effectiveness.

- Maintenance Streamlining: Regular maintenance schedules simplify workforce deployment and spare part stockkeeping.

Export Readiness & Worldwide Acceptance

Industries across the globe anticipate adherence to international benchmarks:

- Paperwork & Standard Awareness: Appropriate certifications, material validation, and traceability are vital for foreign markets.

- Global Industry Demand: Purchasers in major mining centers such as Australia, South Africa, and the Middle East expect proven reliability.

- International Buyer Needs: Conformance with ISO guidelines and material specifications secures entry into worldwide industrial undertakings.

Value of Seasoned Manufacturers

Producers with extensive sector familiarity offer several upsides:

- Design Prowess: Engineering tailored for distinct industrial settings.

- Sector Background: Familiarity with operational hurdles across mining, cement, metal, and ceramic fields.

- Dependable Supply: On-time delivery and quality assurance are crucial for uninterrupted plant function.

KEDAR RUBBER PRODUCTS PVT LTD utilizes decades of know-how to create durable [Lid-Plug-Discharge] components relied upon throughout India and global industrial arenas.

About KEDAR RUBBER PRODUCTS PVT LTD

KEDAR RUBBER PRODUCTS PVT LTD stands as a premier fabricator of industrial wear mitigation solutions, serving the mining, cement, metal, ceramic, and bulk material conveyance sectors. Focusing on Ball Mill Rubber Liners, Ceramic Wear Defence Systems, and Conveyor Arrangements, the firm merges engineering skill with precise fabrication.

For further insights, explore their official web presence: 👉 https://www.kedarrubber.com/

Supporting industrial centers across India, including Jamshedpur (Jharkhand), Bhilai (Chhattisgarh), Durgapur (West Bengal), Ahmedabad (Gujarat), and Pune (Maharashtra), KEDAR RUBBER PRODUCTS PVT LTD guarantees equipment reliability through long-lasting, high-performing parts.

Summary

In demanding industrial settings, wear defence is not optional—it is fundamental. The Lid-Plug-Discharge offers a practical, engineered solution to reduce grinding, cushion shocks, and extend the service life of essential equipment.

By understanding materials science, bespoke needs, and operational considerations, plant engineers can improve plant efficiency and reduce downtime. Selecting experienced fabricators like KEDAR RUBBER PRODUCTS PVT LTD secures enduring dependability for industrial activities.

Main Takeaways

- Wear guarding improves equipment longevity.

- Trustworthy parts boost operational output.

- Suitable for mining, cement, metal, ceramic, and bulk handling sectors.

- Sustained performance reduces the need for maintenance.

- Internationally relevant for industrial zones and export-ready uses.

Current Frequently Asked Questions

Q1. What is the typical service duration for a Lid-Plug-Discharge?

A1. Duration varies based on material makeup and operating setting, but generally falls between 3 and 7 years in intense industrial use.

Q2. Which sectors benefit most from the Lid-Plug-Discharge?

A2. Mining, cement, metal & steel, ceramics, power generation facilities, and bulk material movement operations see significant gains.

Q3. How often should the Lid-Plug-Discharge be checked?

A3. Regular inspections every 3–6 months are advised, with prompt review following significant impacts or unusual wear.

Q4. Should I opt for rubber or ceramic wear defences?

A4. Rubber dampens impact and reduces material fatigue; ceramic offers superior abrasion resistance.

#BallMillRubberLiner #CeramicWearProtection #RubberLining #MiningSolutions #BulkMaterialHandling #ConveyorSolutions #kedarrubberproduct #WearProtection #IndustrialManufacturing