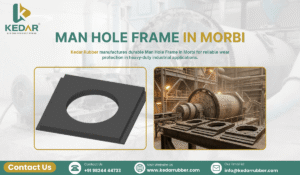

Kedar Rubber Products Pvt Ltd: Man Hole Frame in Morbi for Heavy-Duty Industrial Equipment Design and Long-Term Performance

In demanding industrial settings, the dependability of machinery is key to keeping operations running, ensuring staff safety, and managing expenses. Mining sites deal with continuous scraping of rock and liquid mixtures, while cement factories face extreme heat, heavy dust, and constant vibration. Ceramic makers handle tough, abrasive raw materials, and systems that move large volumes of material operate with minimal downtime. In situations like these, a Man Hole Frame in Morbi is vital for providing secure entry, structural soundness, and lasting sealing performance in challenging industrial gear.

Across these sectors, unexpected stoppages often stem from small but crucial entry points on machines—such as inspection panels, access ports, and service openings. When these access points aren’t well thought out or adequately shielded, they can lead to leaks, structural collapse, or safety hazards.

Worldwide industry needs show a clear trend towards long-lasting, easy-to-service, and tailored wear protection parts. Amongst these parts, the Frame for a Man Hole holds a vital place. Even though it’s often overlooked, it directly impacts how well equipment seals, how safely maintenance crews can get in, and the long-term structural soundness of grinders, chutes, tanks, and process containers.

Industrial Hurdles Driving Need for Manhole Frames

Factories in mining centers, ceramic hubs, steel zones, and bulk transfer centers face similar issues, regardless of location.

- Wear: Inner surfaces near access points suffer constant abrasive wear from material movement, especially in grinding mills, liquid tanks, and transfer spots.

- Impact Forces: Large material pieces, grinding balls, or clinker can hit access openings during operation, causing concentrated stress around the frame perimeters.

- Rusting: Contact with chemicals, moisture infiltration, and process liquids can accelerate rusting of metal structures if the seal fails.

- Stoppages: Frames that don’t seal well or get misshapen lead to frequent service breaks for changing seals, tightening bolts, or fixing the structure.

- Service Expenses: Recurring problems around access points increase the need for replacement parts, labour hours, and safety oversight personnel.

At mining and metal-handling sites worldwide, these difficulties have heightened the need for specially designed frame solutions that offer resistance to wear, impact absorption, and consistent sizing.

What is a Man Hole Frame?

A Man hole Frame is a structural component that also provides a seal, fitted around access holes in industrial equipment such as grinding mills, tanks, hoppers, chutes, and reactors. Its main jobs are to:

- Maintain the correct size of the opening

- Hold covers or doors firmly in place

- Ensure a good seal under operational pressures

- Permit safe and repeated entry for checks and upkeep

Unlike frames that are made, industrial manhole frames are engineered to withstand shifting forces, abrasive conditions, and repeated opening and closing without warping or leaking.

There’s no need to over-engineer these components for sales advantage. The focus should be on reliable function, compatibility with adjacent liners or outer casings, and dependable performance across the equipment’s planned working life.

Uses Across Various Sectors

Mining

In mine facilities, these frames are often found in grinding mills, liquid tanks, and separation cells. They allow entry for liner inspection, adding grinding media, and cleaning the inside while resisting abrasive slurry and impacts from grinding media.

Cement

Cement factories use these frames in raw material grinders, coal mills, ductwork leading to preheaters, and storage bins. These frames must withstand dust ingress, vibrations, and thermal changes without losing their sealing effectiveness.

Metal & Steel

In steel and alloy production, the access frames are subjected to scale, fine metal particles, and shifting temperatures. Structural soundness and safe access are crucial in tight areas.

Ceramic

Ceramic producers frequently work with sharp, grinding raw substances. Frames fitted to mixers, blenders, and material containers must resist rapid edge wear and prevent material from escaping.

Power Stations

In power plants that burn fuel or use self-generated power, these frames are fitted to ash-removal systems, liquid tanks, and ducts, where wear and rust are everyday occurrences.

Bulk Material Handling

Conveyor belts, transfer chutes, and storage hoppers depend on these access points for inspection. Poorly designed frames in these zones quickly become points of failure.

Material Science & Engineering Aspects

Experienced factory engineers often note that failures around access points are seldom due to a single cause. The choice of material is a deciding factor.

- Qualities of Rubber: Frames made of or incorporating rubber offer flexibility, impact absorption, and resistance to shaking. Properly mixed rubber lessens stress transfer to connected structures and enhances sealing.

- Use of Ceramics: In areas with heavy abrasion, ceramic pieces may be built into the frame’s edge to protect it from material scraping. The toughness of ceramic significantly boosts wear resistance, where rubber alone might deteriorate.

- Principles of Wear Resistance: How well something resists abrasion depends on a balance of toughness rather than just raw material strength. Materials that are too hard can crack under impact, while those that are too soft will wear down quickly.

- Impact Dampening: Frames lined with or backed by rubber absorb energy from falling material, reducing stress on adjoining liners or outer casings.

Producers with a long history in the industry know that how materials behave under actual working conditions is more critical than lab results alone.

Design & Customization Needs

Industrial equipment is rarely the same across different sites. Manhole frames must be designed to suit:

- The shape of the equipment and the thickness of its shell

- The pattern for bolts and the design of the cover

- Needs for integrating liners

- The limited space available for maintenance access

Custom sizing ensures loads are distributed correctly and the seal is effective. Tailored design prevents high-stress points, uneven gasket compression, and early failure.

Manufacturing Quality & Process Control

Precise manufacturing directly affects how well a part performs on site. Key things to check include:

- Accurate control of dimensions

- Consistent mixing of rubber compounds

- Controlled heating (curing) processes

- Strength of the bond between materials

Consistency across production batches ensures that replacement frames will act as expected, allowing maintenance teams to plan shutdowns confidently rather than react to sudden breakdowns.

Installation & Service Needs

Well-designed frames make setup easier by aligning smoothly with existing openings and fastening systems. Less time spent installing means shorter service interruptions.

From a service viewpoint, robust frames:

- Lessen the need to replace gaskets constantly

- Keep the seal effective over many times of opening and closing

- Provide a safer entry for inspection crews

Predictable service schedules are particularly valuable in industries that operate continuous processes.

Safety & Operational Dependability

Safety is intrinsically linked to equipment configuration. Inadequately sealed or deformed access portals can provoke substance escape, pressure release events, or abrupt lid failure.

Dependable access cover frames aid in:

- More secure entry into confined spaces

- Diminished likelihood of sudden substance expulsion

- Enhanced operator assurance during check-ups

Equipment longevity and personnel well-being are closely intertwined in heavy-duty facilities.

Economic Efficiency Across the Equipment Lifespan

Cost effectiveness is achieved by minimizing unforeseen outages and streamlining maintenance planning, rather than prioritizing lower initial material costs.

Over the complete equipment lifespan, robust access cover frames assist in achieving:

- Fewer necessary emergency stoppages

- Reduced expenditures on maintenance labour

- Prolonged service duration for liners and main structures

These advantages accumulate over many years of service, especially in high-volume processing plants.

Export Qualification & Universal Acceptance

Global industrial purchasers anticipate uniformity, transparent documentation, and awareness of operating environments across diverse locales. Components destined for export must satisfy:

- Expectations for precise dimensions

- Mandates for material provenance

- Suitability for various climates and industrial sectors

Providers serving international arenas recognize these prerequisites and adjust their manufacturing and quality protocols accordingly.

The Importance of Seasoned Producers

Manufacturers with extensive experience in the sector understand the real plant challenges—beyond mere blueprints and specifications. Engineering proficiency guarantees:

- Design choices driven by the actual application

- Trustworthy selection of materials

- Continuous provision of support

For Original Equipment Manufacturers, Engineering, Procurement, and Construction contractors, and maintenance crews, reliable parts reduce both project and operational hazards.

Concerning KEDAR RUBBER PRODUCTS PVT LTD

KEDAR RUBBER PRODUCTS PVT LTD is a seasoned industrial producer serving the mining, cement, ceramic, metal, and bulk material handling industries throughout India and overseas. The firm focuses on engineered rubber products, wear defence protection systems, and custom components tailored for demanding operational environments.

With a comprehension of real-world plant difficulties and long-term equipment performance, KEDAR RUBBER PRODUCTS PVT LTD supports industries with reliable, thoughtfully engineered solutions founded on manufacturing rigour and practical engineering judgment.

Further particulars are accessible at 👉 https://www.kedarrubber.com/

Summary

Man Hole Frames might seem like secondary parts, yet their influence on facility safety, maintenance streamlining, and equipment reliability is substantial. When correctly engineered, they support smoother processes, safer assessments, and more predictable maintenance schedules.

In challenging industrial settings, focusing on such vital particulars helps facilities sustain consistent output and operational stability.

Main Takeaways

- Manhole frames occupy a vital function in equipment accessibility and sealing integrity

- Appropriate material choice enhances resistance to wear and impact absorption

- Design tailored to the specific use reduces maintenance complexities

- Dependable frames contribute to safer site operations

- Long-term functioning supports better cost performance and operational continuity

Current Frequently Asked Questions

1. What is the usual service life expectation for an industrial access cover frame?

Service life depends on operating conditions, material selection, and maintenance practices.

2. Are these access frames appropriate for harsh mining environments involving abrasion?

Yes. When fitted with suitable rubber or ceramic linings, they function dependably in abrasive mining conditions.

3. At what interval should access cover frames undergo inspection?

Inspections are generally synchronized with planned outages or line reviews, based on the facility’s production cycles.

4. Comparing rubber versus ceramic wear solutions—what are the distinctions?

Rubber provides good shock absorption and pliability, whereas ceramic offers superior resistance against abrasive wear.

#ManHoleFrame #MorbiIndustry #HeavyDutyEquipment #MiningSolutions #CementPlants #CeramicIndustry #BulkMaterialHandling #WearProtection #IndustrialReliability #KedarRubberProducts